Bee Products

Introduction

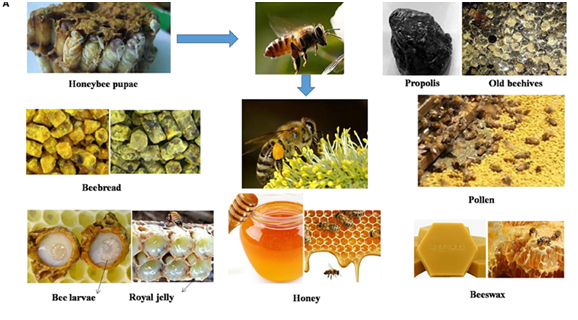

Honeybee-derived products are used as traditional complementary medicines worldwide, especially in oriental countries.

Fig 1. bee products

Honey

Honey is defined as "the sweets substance produced by honeybees from the nectar of blossoms or from secretions on living plants, which the bees’ collect transforms and store in honey combs”. Honey bee produces dense and stable energy food called as nectar which ripened into honey. Honey is prepared by bees from plant nectars, from plant secretions and from excretions of plant sucking insects (“honeydew”). The Food Standards Code defines it as “the nectar and saccharine exudations of plants gathered, modified and stored by the honey bee”. Honey is the most wonderful gift of God and Mother nature to mankind. The bee gives man honey, the liquid gold of nature, a product incomparable to anything else in terms of its nourishment and healing properties.

table pending

Be Pollen

Pollen is the male gametophyte of flowers. Bee pollen, which is also called “bee bread” and sometimes “ambrosia” is a staple food for honey bees and their young. Commercially traded pollen is mainly pollen collected by the honey bee Apis spp. for the purpose of feeding its larvae in the early stages of development. Collected flower pollen is accumulated as corbicular pellets in pollen baskets on the rear legs of the honey bee and it is a mixture of these pellets that comprises bee pollen. When visiting flowers, bees touch the stamens and their bodies become covered with pollen dust. The bees use their hind legs to compress the pollen into the pollen baskets. The bees moisten the pollen with mouth secretions which help the pollen to cling together and to the basket hairs. These secretions contains different enzymes, e.g. amylase, catalase etc. A pollen load contains up to 10% nectar, which is necessary for packing. One pollen granule contains from one hundred thousand to five million pollen spores each capable of reproducing its entire species.

Pollen Collection by bees

It has been observed that honey bee workers choose pollen based on the odor and physical configuration of the pollen grains rather than based on nutritive value. A typical size honey bee colony (approximately 20,000 bees) collects about 57 kg of pollen per year. On average, 15-30% of a colony's foragers are collecting pollen. A single bee can bring back a pollen load that weighs about 35% of the bee's body weight. Bees carry this pollen on their hind legs, on specialized structures commonly called "pollen baskets" or corbicula. Once pollen is brought back to the colony, the workers condition it by adding glandular secretions containing enzymes and acids that prevent harmful bacterial activity and prepare the pollen for long-term storage. Stored pollen often is called "bee bread". Bees also add beneficial microbes to the pollen and they produce enzymes that help the pollen release nutrients and amino acids. Bee bread is consumed by a colony relatively quickly and only stored for a couple of months if there is a surplus. A colony's annual requirement for pollen has been estimated to range from 15 to 55 kg.

Bees require pollen for growth and development. Immature (larval) bees are fed a mixture of brood food and bee bread. Newly emerged bees consume bee bread so that their bodies can complete development. The amount of pollen required to rear a single worker larva has been estimated at 124-145 mg, this containing about 30 mg of protein. The minimum level of protein required for honey bees has been estimated to be between 20-25% crude protein. Pollens with protein levels in this range are more useful to colonies and allow them to meet their protein requirements readily. A diet of high protein pollen increases worker bee longevity, while brood rearing is reduced when supported by pollens low in protein.

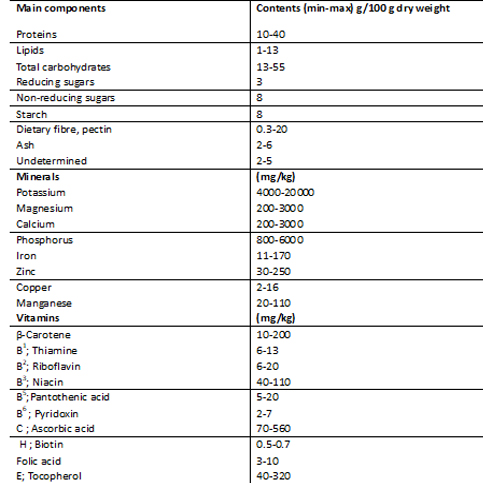

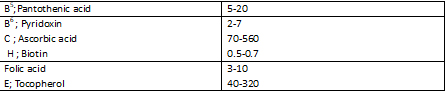

Composition of bee Pollen

Table: composition of bee pollen

Propolis

Propolis (bee glue) is a sticky dark coloured material that honeybees collect from living plants, mix with wax and use in construction and adaptation of their nests. The term ‘propolis’ was used by authors in Ancient Greece: pro (for, in front of, e.g., at the entrance to) and polis (city or community); a substance that is for or in defence of the city or hive. Bees apply propolis in a thin layer on the internal walls of their hive or other cavity they inhabit. It is used to block holes and cracks, to repair combs, to strengthen the thin borders of the comb, and for making the entrance of the hive weather tight or easier to defend. Propolis also is used as an “embalming” substance to cover hive invaders which bees have killed but cannot transport out of the hive. Bees make use of the mechanical properties of propolis and of its biological action: bee glue contains the putrefaction of the “embalmed” intruders, it is responsible for the lower incidence of bacteria and moulds within the hive than in the atmosphere outside.

The action against micro-organisms is an essential characteristic of propolis and it has been used by human beings since ancient times for its pharmaceutical properties. Propolis is currently a popular alternative medicine in various parts of the world, including Japan and the European Union. It is a complex mixture of substance collected by honeybees from buds or exudates of plants (resin), beeswax and other substances, such as pollen and sugars. Plant source, physicochemical properties and antibacterial activity are important parameters for propolis quality evaluation. Propolis possesses antibacterial, antifungal and antiviral properties and many other beneficial biological activities: antiinflammatory, antiulcer, local anaesthetic, hepatoprotective, antitumor, immunostimulating, etc. For this reason propolis is widely used as a popular remedy in folk medicine, in apitherapy, as a constituent of “biocosmetics”, “health food” and for numerous further purposes.

Resin Palnt Sources

The chemical composition of bee glue is very complex and depends on the flora in the areas where it is collected. To understand what causes the differences in chemical composition, it is necessary to keep in mind the plant origin of propolis. The knowledge about plant sources of propolis could be useful as a basis for the chemical standardization of propolis.

Importance of the knowledge of plant sources

The knowledge about plant sources of propolis is not only of academic interest. It could be useful as a basis for the chemical standardization of propolis. Bee glue could be easily characterized using its plant source, which might be established by simple TLC, HPLC or GC comparison. As far as the composition of the corresponding plant exudates is known, this method gives information about the qualitative composition of the sample. For example, speaking about “poplar type” propolis, it is clear that the product is a mixture of flavonoid aglycones, hydroxycinnamic acids and their esters. In addition, knowledge of propolis plant sources is important to beekeepers to be sure that their bees have the proper plants in their flight range. It is known that colonies suffer when they cannot collect propolis, bees are even said to use “propolis substituents” like paints, asphalt and mineral oils which could severely threaten pharmaceutical uses of bee glue.

Chemical Composition

Processing of Propolis

Extraction is normally done in 95% ethanol. Put about 30-40% propolis in alcohol and leave for 1-2 weeks. However shake it at intervals. Filter through muslin cloth. The efficiency of extraction depends upon the concentrations of ethyl alcohol and proportion of propolis to alcohol used for extraction as also the time for extraction. The extract in alcohol can be used as such or the solvent is allowed to evaporate and a paste is prepared for use.

Oil Extraction : Ten grams of propolis is put in 200 ml of olive oil or 100ml of linseed oil. Heat gently in water bath for 10 min. at 50°C, stirr continuously, filter and store in sealed containers in dark. Refrigerated storage is recommended.

Aqueous extracts can be obtained by soaking propolis for several days or by boiling it in water. Yield of active ingredient is lower than the extraction with alcohol but it does show some antibiotic and fungicidal properties.

Extraction can also be made with liquid ammonia especially from hessian cloth kept-below the inner cover or other lower quality sources and be used for painting hive parts or other wooden articles.

Royal Jelly

The classical concept of “adequate nutrition,” that is, a diet that provides nutrients in sufficient quantities to satisfy particular organic needs, is being replaced by the concept of “optimal nutrition,” which includes, besides nutrients, the potential of food to promote health, improve general well-being and reduce the risk of developing certain illnesses. This is where functional foods, also known as designer foods, therapeutic foods, superfoods, or medicinal foods, play their part. The market for functional foods is increasing at an annual rate of 15–20%. A functional food may be natural or be obtained by eliminating or modifying one or more of its basic components. Some components may also be added to food to make them “functional” among them ω3 fatty acids, vitamins, probiotics, fibre, phytochemicals, bioactive peptides and phytosterols may be named. Among foods that possess potential health benefits are those originating from the beehive, namely honey, propolis and royal jelly. Royal jelly is a viscous substance secreted by the hypopharyngeal and mandibular glands of worker honeybees as an essential food for the queen bee larva and for the queen herself. If fed to an ordinary female bee in the larval stage, royal jelly will transform her into the queen bee. As a queen, she will grow 1½ times normal size, become extremely fertile and lay over a thousand eggs each day. Incredibly, she may live over five years while all the other bees live only a few weeks. The only difference is that she receives royal jelly while the others don’t

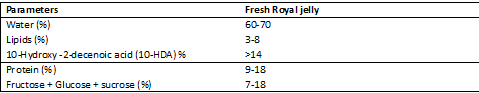

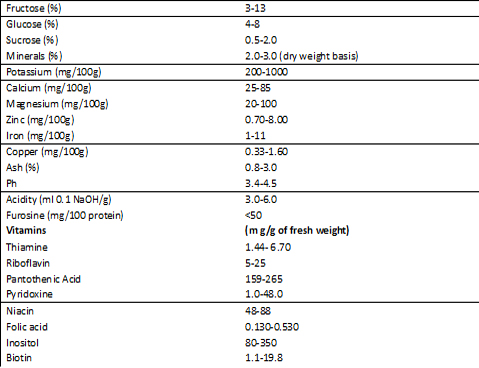

Chemical Composition of Royal Jelly

Be Venom

The use of weapons as defence against enemies was one of the major factors that favoured the evolution of social life in insects. In the eusocial Aculeate Hymenoptera, the stinging apparatus and the venom, originally evolved as devices to paralyse preys, became arms to defend the colony mainly from the attacks of vertebrate predators. The venom gland of worker bee is located in posterior portion of the abdomen, between the worker’s rectum and ovaries. The two glands (Dufours and Venom gland) associated with sting apparatus of the worker produce venom. The venom gland is a thin long, distally bifurcated integumentary gland with cuticular lining. It consists of a secretary filamentous region, connected to a reservoir at its proximal portion, in which the venom is stored. The small flat cells also bearing canaliculi form the distal region of the reservoir where their products contribute to venom composition. The workers sting only once, which leads to their death.

Bee venom contains 88% water. These oppose the inhibiting action of the nervous system and also stimulate the heart and adrenal glands. Sulphur is the main element in inducing the release of cortisol from the adrenal glands which protects the body against infections. The venom also contains mineral substances, volatile-organic acids, formic acid and some antibiotics. Venom is one of the products of honeybee, which is an important component in the pharmaceutical industry. Use of naturally available substances as medicines, in Asia represents a long history of human interactions with the environment. The medicinal value of these substances lies in some chemicals that produce a definite physiological action on the human body. The venom production is usually complete within two weeks and then glands start to degenerate in the adults. Not only has the age affected the venom composition but also seasonal factors like availability of food sources etc. A newly emerged bee has very little venom content, but the amount gradually accumulates with age, to about 0.3 mg in a 15 day old A. mellifera worker bee, after the age of 18 days no additional venom is produced. Subsequently, the weight of the venom in the venom sac remains unchanged. Bee venom has interesting pharmacological properties and is used in the treatment of various health conditions such as arthritis, rheumatism, pain, cancerous tumors and skin diseases.

Physical Characteristices of Venom

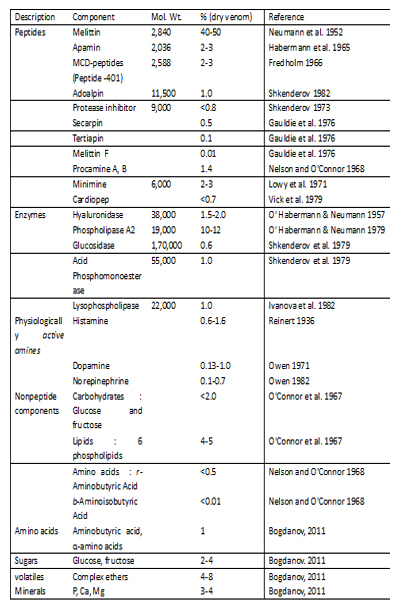

Table 1. Biochemical Compositions of the bee venom (Kim, 1992).

Bees Wax

Beeswax is one of nature’s amazing materials. Human societies have long valued beeswax, and today it remains an expensive product with many uses. Yet some beekeepers remain unaware of the value of beeswax, and even throw it away. What waste that represents, for bees consume around eight kilograms of honey to produce just one kilogram of beeswax. The beeswax is a complex substance and is an important product of beekeeping. Bees need wax as construction material for their combs. They produce it in their wax glands, which are fully developed in 12 to 18 days old workers. In older bees the wax glands diminish their activity. However in emergency situations wax-synthesis can be reactivated. Greatest quantities of wax are produced during the growth phase of bee colonies, under moderate climate conditions during April to June. The process of wax secretion is signaled by hive activity at optimum temperature (370C). It is secreted as a liquid from four pairs of wax glands on the ventral surface of the abdominal tergites (plates on the underside of a bee’s body). The liquid wax spreads over the surface of these plates, and, on contact with air, the wax hardens and forms a tiny wax scale on each tergite, which can be seen as small flake of wax on the underside of the bee. A worker honey bee produces eight of these scales of wax every 12 hours. About one million of these wax scales are needed to make one kilogram of wax. Bees use the stiff hairs on their hind legs to remove the scales of wax and pass them on to the middle legs, and then to the mandibles (jaws) where wax is chewed, and salivary secretions become mixed with the wax. When it is the right consistency, the new wax is used for comb construction or used to seal honey cells.

Composition

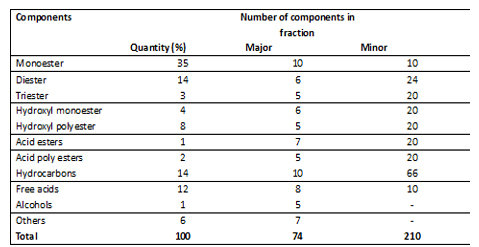

Table : Composition of wax

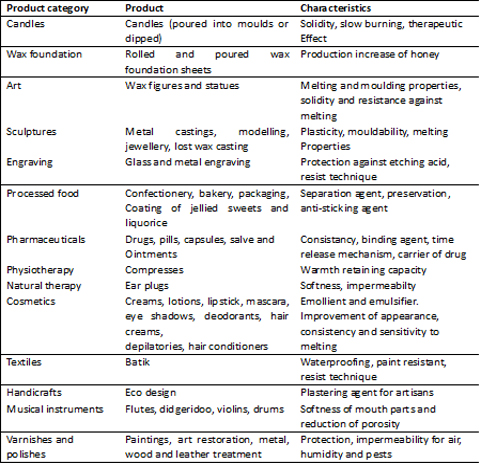

Value Added Products of Honeybees

Candle making

Around 20 percent of the beeswax trade is used for candle making. Beeswax candles are less common and more expensive than candles made from paraffin wax. In the past church candles had to be made of 100 percent beeswax, and this is still followed in some societies. Candles made of beeswax have been used by mankind in religious ceremonies since a very long time. Beeswax candles can be made by different methods: pouring, dipping, rolling, extruding, drawing and pressing. The different methods of candle making are described in detail elsewhere. Since beeswax has a higher melting point than most paraffin waxes (most of which melt between 48 and 680C) beeswax candles remain straight at higher ambient temperatures. Waxes with a melting point above 880C do not perform well during burning.

Table: uses of beeswax